The durable material known as a Wood-Plastic Composite (WPC) sheet is created by mixing thermoplastic resins with wood fibres or powder. It combines the strength of plastic with the beauty of genuine wood, making it appropriate for a range of design and construction uses. WPC sheets are frequently utilised as a sustainable substitute for conventional wood products because of its reputation for being impervious to moisture, rot, and pests. Shop WPC Sheets from Greh Sajjaa.

Composition of WPC Sheet

Wood fibres (or powder), thermoplastic resins (such as PVC, polyethylene, or polypropylene), and additives for stability and performance improvement are the usual components of WPC sheets.

The precise proportion of plastic to wood might change based on the application and desired qualities.

Composite materials known as wood-plastic composites (WPCs) are composed of thermoplastics like polythene (PE), polypropylene (PP), polyvinyl chloride (PVC), or polylactic acid (PLA) with wood fibre or flour.

A composite material is the ultimate result, combining the enhanced functionality and durability of plastics with the natural beauty of wood. The thermoplastics provide the wood fibres more strength, stiffness, and visual appeal while also increasing their dimensional stability, water resistance, resistance to rot and decay, and natural look.

The advantages of WPC sheets over more traditional materials like wood or pure plastic are numerous. They are used by many designers, architects, and homeowners seeking a reliable and aesthetically pleasing material because they may mimic the natural appearance of wood while offering increased longevity and less maintenance needs.

Properties of this Sheet

- Water Resistance: Although the level of water resistance varies, they provide adequate protection against water damage.

- Eco-Friendly: Because WPC sheets can be manufactured from recycled materials and eliminate the need for forest harvesting, they are seen as a more sustainable option to traditional wood.

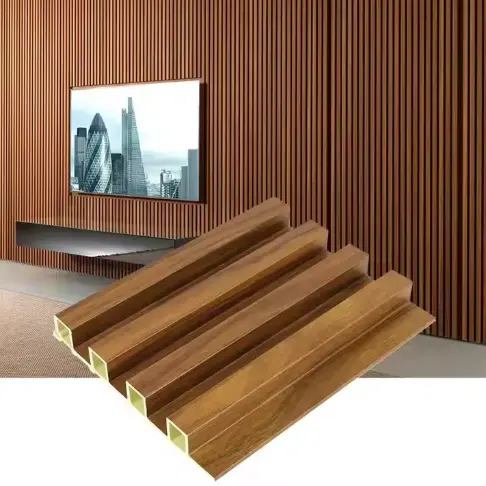

- Aesthetics: They come in a range of hues and finishes and may be made to resemble real wood.

- Versatility: WPC sheets are appropriate for a range of applications due to their ease of cutting, shaping, and installation.

Uses

- Applications outside include: siding, decking, cladding, and outdoor furnishings.

- Interior Uses: Modular kitchens, flooring, furniture, and wall panels.

- Additional Uses: Displays, signage, and other building initiatives.

Benefits

When compared to more conventional materials like wood, WPC (Wood Plastic Composite) has several advantages, such as increased durability, moisture resistance, low maintenance, and environmental friendliness. WPC is very adaptable and may be utilised for a variety of purposes, such as furniture, wall cladding, decking, and flooring.

- Durability & Longevity: WPC is a long-lasting and sturdy choice because of its reputation for being resistant to rust, deterioration, and pests. It is resistant to moisture and humidity, severe weather, and high foot traffic.

- Moisture Resistance: WPC is extremely resistant to moisture because to its non-porous composition, which keeps it from warping, swelling, or decaying. This makes it appropriate for places like kitchens, baths, and outdoor locations that are likely to have significant humidity or water exposure.

- Low Maintenance: Unlike traditional wood, which may need to be stained, painted, or sealed on a regular basis, WPC requires less maintenance. WPC can be kept looking brand new with a quick wash or wipe.

- Simple Installation: A lot of WPC goods, like as flooring and wall panels, are made to be easily installed with snap-locking technology, which saves money and effort.

- Versatility: WPC offers a vast array of hues, textures, and finishes, enabling imaginative design possibilities. It has several uses, ranging from flooring and furniture to wall cladding and decking.

WPC sheets use recycled resources and less virgin plastic by mixing thermoplastics with wood fibres or flour. This reduces waste and encourages resource efficiency. Furthermore, WPC sheets last longer than conventional wood, which lowers replacement frequency and the resulting environmental effect.

They are also environmentally beneficial because they don’t require chemical treatments due to their resilience to decay, wetness, and insects. Selecting WPC sheets not only offers strong and adaptable materials but also helps create a greener future as sustainability becomes a top concern in many sectors.

WPC Sheets’ special qualities and adaptability have transformed a number of sectors. WPC sheets have shown their value in a variety of applications, including building and construction, automotive, furniture manufacture, signs, and packaging. WPC sheets are expected to be crucial in determining the direction of these sectors as the need for durable and ecological materials grows.